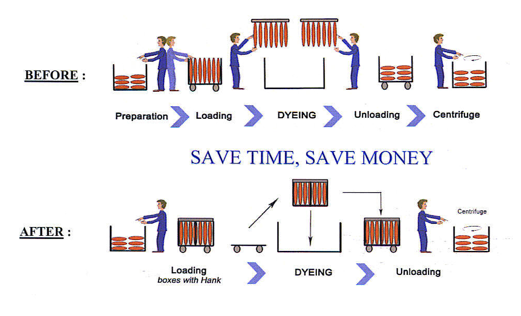

BEFORE

Traditionally, the Hank Dyeing process is labour intensive.

The various operations involved are not only time consuming,

But also involve significant manual handling through lifting of

The hank on sticks and then placing on the lid.

This today can give rise to concerns with regards to

Health & Safety within the workplace, especially when unloading after the dyeing process, as the hanks are wet and, therefore, the weight may be more than 30 Kg (66 pounds)

Callebaut de Blicquy has developed a unique system that is already in use at many modern dye house, whereby loading and unloading of the hanks is done much more quickly and involves less manual effort.

Hanks are directly loaded in boxes (this manipulation is done at waist height).

The lid is positioned above the boxes. And with a simple and effective system of hooking, all is transported into the dyeing vat.

Not only, this system is faster and less stressful, but also, enables higher productivity within the dye house.

In addition, we can propose you a variant; A most efficiency system. For the loading and the unloading, the Boxes are directly set on trolleys in inox (that are easily positioned and adapted).

The moving of the boxes inside the dye House (preparation-dyeing vat-hydro extractor,…), is easier and faster

TECHNICALS INFORMATIONS

- Capacity from 5 to 3 000 Kg (11 to 6,615 pounds) in a single bath

- Automatic loading

- For wool acrylic yarn (especially carpet yarns)

- Significantly faster and easier handling of the hanks during the loading and the unloading (as is indicated in the schema)

ADVANTAGES

- Preserve the resource in water

- 50% saving

- Perfect dyeing

- Better working conditions

- Fast return on investment

- Easy use