Pressing material can be done a large range of materials, whatever the yarn’s number and the fineness of the raw or the denier. The choice of the press will be done according the material and its form : bobbins, raw, bumps, muffs, etc…

These presses can receive all kind of materials, such as Wool, Polyester, Acrylic, Cotton, Polyamide, viscose and theirs blend on bobbins.

It is very important to underlines than the pressing operation enable to get a better homogeneity of the package to treat and consequently, enable to have a Better Levelling effect during the post treatment as dyeing or bleaching….

The permanent research and development on our pressing systems enable to CALLEBAUT DE BLICQUY to propose a large range of manuals or automatic presses, perfectly adapted to all kinds of textile material.

THE CALLEBAUT DE BLICQUY’s PRESSES

Three types of Press :

- Press for bobbins winded on support which can be pressed

- Press for Raw and Taw

- Press for Bumps high density

1. Press for bobbins with new system to Load/Unload easier the carriers (See the movie)

Thank to its pressing’s head 3 axes, and its rotating base, its use is very friendly

New : The rotating base receiving the carriers can be also equipped with an additional UP & DOWN system. This enable also to use this post’ work as a tool to help the operator for the bobbins Loading/Unloading on the carriers. So, with a low additional cost, this work can become less laborious ans enable to improve considerably the productivity during the preparation of the carrier before dyeing.

2. Press for Raw & Taw

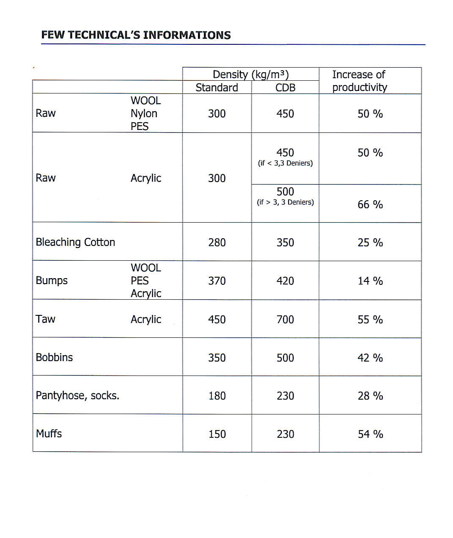

- Thanks to its capacity to press in very high density, this press specially designed to receive the carriers type “ packing carriers ”, enables to increase seriously the productivity of dye plant. Up to 700 kg/m³

- The capacity to press is adapted to the material and its density. An high pressing’ rate is helpful to ensure a better levelling and a perfect reproducibility during the Dyeing or Bleaching treatments. Very low liquor ratio.

- Our different automatic versions offer also the possibility to prepare the carriers without any manpower : Carrier’s filling / Handling and Locking of the cover / Intermediary and final pressing / Moving of the carriers, etc…

3. Press for Bumps High Density

3. Press for Bumps High Density

- The hydraulic pressing enables an high density Loading of the Bumps, up to 420 kg/m³

- An high pressing’ rate is helpful to ensure

- a perfect levelling

- a perfect reproducibility

and also to cancel completely the risk of felting during the dyeing treatmant

The high density’ rate enables also to increase seriously the productivity of the dye plant, Comparatively to the standard presses with lower density.